Insulated Doors Spiral 80 Cold Room

Insulated door developed with specific resistance at low temperatures : cooling and refrigeration doors are ensured down to -25°C and is perfect for food and refrigeration sectors.

Patented vertical scrolling is made of high density polyethylene and the curtain is composed of aluminum panels or double wall steel with high thermal-acoustic insulation. The winding space is very low. It does not require anchoring to the ceiling.

Insulated Doors Spiral 80 Cold Room: features and benefits

Insulated industrial roll-up shutters are a technological evolution in the field of doors, with the goal of dividing operating zones marked by different acoustic and thermal intensities or intended for different uses.

Thermicroll® Spiral Door ISO 80 Cold Rooms industrial doors are part of the range of insulated shutters, which have been committed for years to providing products capable of supporting and managing every business logistics problem.

Spiral 80 Cold Room insulated door is the top of our company’s products, designed to guarantee an unrivalled level in terms of speed, safety and isolation between environments.

The thickness of the panels and their shape are the essential elements for operating in very rigid climatic conditions. In fact, this model differs from other Thermicroll industrial doors because of its specific resistance to harsh temperatures and therefore to refrigerated environments.

The patented circular spiral winding is made of high-density polyethylene and the covering is composed of double-walled aluminium or steel panels with high thermal and acoustic insulation and the possibility of inserting polycarbonate windows.

The main advantages of Spiral 80 Special Application insulated doors are represented by extreme response speed, minimum displacement noise, absolute safety, superior winding with reduced space requirements, thanks to the special processing of the curved insulated profile. In addition, ceiling anchors are not required, unlike traditional speed doors. The ground impression is completely absent when the damper is open. Last but not least, it is the very attractive aesthetics, able to provide the customer with an excellent business card of its activity.

These and other innovations make Thermicroll® the leading company for industrial dampers in design, research and development.

Spiral 80 Special Application: patented Italian speed doors

The structural simplicity of this industrial door allows to reduce costs, maintenance and assembly times, but at the same time enhances the quality and functionality.

This industrial door, which uses mechanical and electrical components of the highest quality, is entirely studied, designed and built in Italy, in one of the company’s various locations.

The first guarantee on insulated doors is given by repeated tests on all industrial doors during the various phases before and after installation.

Specifically, this model has been validated to withstand 1 million opening and closing cycles: the Cold Room doors are completely reliable thanks to the numerous thermal tests carried out in the various phases of production and installation.

All our insulated roll-up shutters comply with the 12453-12445/EC and UNI EN 13241-1/EC regulations and are certified as exclusive and original products, unique in their strength, practicality, functionality and quality.

If the ISO 80 Cold Room insulated door is not the most suitable door for your needs, you can see the other Thermicroll insulated shutters: Spiral 80 insulated rapid doors, Spiral door ISO 50 insulated shutters, Spiral 50 SMART insulated rapid doors, Air Flow microperforated shutters.

View the table with technical specifications and download the catalogue!

| THERMICROLL® SPIRAL 80 COLD ROOM TECHNICAL SPECIFICATIONS |

|

| PARAMETERS | SPECIFICATIONS |

| Application | Internal and external |

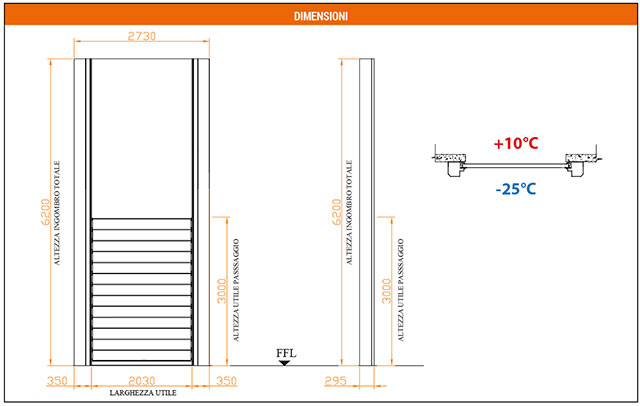

| Maximum dimensions (L x H) | 4000 x 4000 mm |

| Opening speed | Up to 2 m/sec (depending on size) |

| Closing speed | ~ 0,5 m / sec |

| Thermal coefficient | U = 0,7 W/m2K |

| Acoustics | 25 Db |

| Water permeability | Class 3 |

| Air permeability | Class 3 |

| Operating temperature | -5 °C +40 °C |

| Wind load L/H 3000 x 3000 mm L/H 4000 x 4000 mm |

Class 4 3 |

| Structure | Standard: galvanized steel Optional: Epoxy powder coated steel RAL / AISI 304 stainless steel |

| Coat thickness 80 mm | Standard: Aluminium exterior / interior Optional: exterior/interior made of RAL powder-coated steel / AISI 304 stainless steel |

| Spiral | Patented, high density polyethylene PEHD 500 |

| Guides | Patented, high density polyethylene PEHD 500 |

| Control panel | 380 V inverter with microprocessor |

| Power supply | 400 V |

| Frequency | 50 / 60 Hz |

| Limit switch | Encoder |

| Gearbox / Engine | Motorized synchronous with 110 V electric brake for high-frequency intensive use |

| Emergency release | Standard: hand crank/counterweight release Optional: manual chain opening |

| Safety edge (EN 13241) | Standard: integrated in photocell barriers Optional: crushing sensor |

| Wiring | IP 69 plug and play |

| Photocells | 22 active beams up to a height of 2500 mm |

| Durability | 3 million opening and closing cycles with regular maintenance every 6 months or every 150,000 cycles |